Questions and comments can be sent to me at hollace@crosslink.net

Saturday, October 26, 2002

Tuesday, October 22, 2002

Today Rick showed Tracy and I the process for picking up the molds from the lofting. The head of a small nail is gently hammered into the lines at each station which follow the shape of the inside the planking and bottom. A board is then pressed down onto the other side of the head of the nail which transfers the shape. The indents are connected with a smaller batton and pencil line.

The bottom line is established and the wood is cut on the band saw to the shape. A mirror image is made, the width picked up also from the lofting and it's all screwed together. Makes alot of sense, huh?

Got two estimates for lumber for the boats. $$! Will order tomorrow.

October 20, 2002

Drew lines for Plans View on lofting, struck the line with a batton. Measured the stem to find the rabbit line for the lofting.

Drew a sketch of the shape of the stem as seen from above.

October 18, 2002

Screwed the lofting boards to the shop floor. Moved baseline strip from under the boat and placed it along the edge of the plywood. Transferred the frount of stem, three rabbit points along stem, station lines, and transom to the plywood, drawing the lines the full width of the board. Transferred verticle dimensions to one side of the lofting boards to create the profile view, and from the tick strips to the other side of the board for the Plans View (looking straight down or up to the boat)

With a very long batton we struck the lines for the sheer, plank and bottom checking for fairness.

October 17, 2002

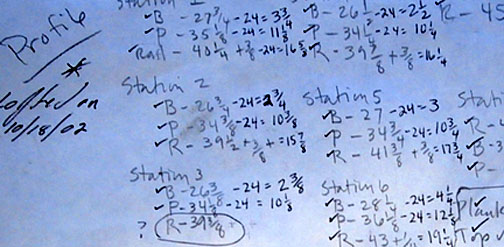

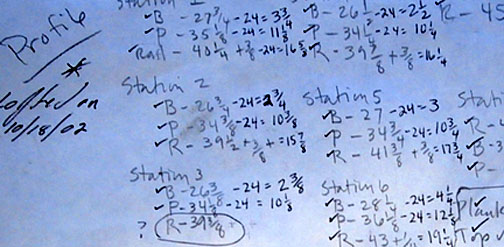

Took measurements from baseline points at each station, which is the floor, at each station vertically to the three points, bottom of boat, plank line and sheer.

Painted two sheets of plywood white to use for the lofting.

Drew lines for Plans View on lofting, struck the line with a batton. Measured the stem to find the rabbit line for the lofting.

Drew a sketch of the shape of the stem as seen from above.

October 18, 2002

Screwed the lofting boards to the shop floor. Moved baseline strip from under the boat and placed it along the edge of the plywood. Transferred the frount of stem, three rabbit points along stem, station lines, and transom to the plywood, drawing the lines the full width of the board. Transferred verticle dimensions to one side of the lofting boards to create the profile view, and from the tick strips to the other side of the board for the Plans View (looking straight down or up to the boat)

With a very long batton we struck the lines for the sheer, plank and bottom checking for fairness.

October 17, 2002

Took measurements from baseline points at each station, which is the floor, at each station vertically to the three points, bottom of boat, plank line and sheer.

Painted two sheets of plywood white to use for the lofting.

October 15, 2002

Set the boat up in the shop, leveling fore and aft & across the beam on sawhorses so we could begin taking the lines. Established a level waterline with string between 2 braces attached to the floor since the painted waterline didn't look accurate. Rick placed the string for waterline by eye. We found the center of the boat (stem to stern) and laid a strip of wood along a chalk line under the boat, then screwed it into the floor.

Dropped points to the floor with a plum line at each of the 8 stations at the sheer. We found the sheer by extending the frame line to outside of the rail, forward of the frames from amidships to stem, and aft of the frames from amidships to transom. We then subtracting the thickness of the rail at that station. A line was drawn square from the sheer point back to the centerline strip under the boat. Points were established for each station in three places, the outside bottom of the boat, the plank line and the sheer.

October14, 2002

Delivered skiff to Finest Kind Wooden Boats, West Boothbay Harbor, Maine

October 12&13, 2002

Towed the skiff from Maryland to Maine

Set the boat up in the shop, leveling fore and aft & across the beam on sawhorses so we could begin taking the lines. Established a level waterline with string between 2 braces attached to the floor since the painted waterline didn't look accurate. Rick placed the string for waterline by eye. We found the center of the boat (stem to stern) and laid a strip of wood along a chalk line under the boat, then screwed it into the floor.

Dropped points to the floor with a plum line at each of the 8 stations at the sheer. We found the sheer by extending the frame line to outside of the rail, forward of the frames from amidships to stem, and aft of the frames from amidships to transom. We then subtracting the thickness of the rail at that station. A line was drawn square from the sheer point back to the centerline strip under the boat. Points were established for each station in three places, the outside bottom of the boat, the plank line and the sheer.

October14, 2002

Delivered skiff to Finest Kind Wooden Boats, West Boothbay Harbor, Maine

October 12&13, 2002

Towed the skiff from Maryland to Maine